In 2016, plans were being finalized for one of the most ambitious capital projects the world had ever seen. While this was rightfully a cause for celebration due to the jobs this would create and the resulting economic boon that would come thereafter, it would be fool-hardy to dive into such a vast project without the correct planning or tools.

Capital projects are a lengthy and expensive process – and the management of one is notoriously tricky to underpin.

That is, until, iHawk came in.

Background

In June 2016, Shell made the decision to construct a world-scale petrochemicals manufacturing plant near Pittsburgh, Pennsylvania, USA. The plant will consist of an ethylene cracker and three polyethylene derivatives units. In November 2017, they completed extensive site preparation and the multi-billion-dollar project entered its main construction phase.

The facility is being built on the banks of the Ohio River in Potter Township, Beaver County, about 50 kilometers (30 miles) north-west of Pittsburgh. The plant is strategically positioned close to both feedstock and the customer base. More than 70% of the North American industrial polyethylene demand originates in the North-East, within a 1,100 kilometer (700-mile) radius of Pittsburgh – this means that the plant’s Pennsylvania location offers customers a short, dependable supply chain.

The project’s scale is impressive with 300 miles of pipe, more than 1,600 items of manufactured equipment (the largest lift – 1,400 metric tons) and 294 pre-assembled modules. The construction workforce reached its peak in 2019 and into early 2020 with up to 8,500 workers on site, including more than 30 contracting companies.

The Task at Hand

Due to the intense level of construction activity, careful planning and continuous information sharing were critical to maintaining project schedules. We knew that managing Pennsylvania’s largest construction project for decades demanded a new way of working with a groundbreaking set of tools.

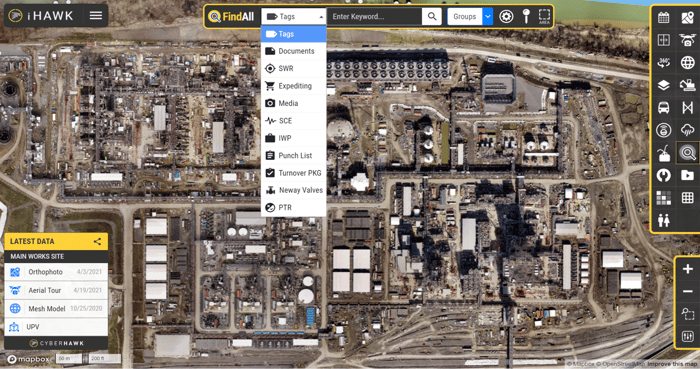

An innovative new digital approach was the answer to managing that informational flow in this vast construction project; that way stakeholders could make informed decisions, develop and adjust execution plans, stay on top of progress and costs, ensure quality and, above all, keep people safe. The team sought to contextualize multiple layers of information in an interactive, map-based platform taking the digitalization to the next level, enabling full progress visibility, operational efficiency and stakeholder communication at all levels.

Interested to learn how iHawk can support your project?

Download your free capital projects capabilities overview pack now!

The Solution: iHawk

In 2017 Shell Polymers selected Cyberhawk’s iHawk – Cyberhawk’s capital project management software – to use as the foundational tool for managing their construction site. The two companies started to collaborate to develop a set of unique, differentiating capabilities to meet a wide range of challenges that the project team was facing.

iHawk, a cloud-based, IoT-enabled visualization interface, enables a community of 700 active users from Shell and 40+ execution contractors to work off the same baseline – in the office, in the field on mobile devices and remotely. 45 interactive, touch-enabled screens have been deployed around the construction and in the future operation team’s offices, in meeting rooms and to collaboration areas. Everyone on the team has a direct, on the spot access to iHawk. The easily accessible smart screens foster collaboration and teamwork and have made iHawk an integral part of all planning and coordination meetings on the construction project.

Today, iHawk combines visual data gathered by the UAVs (drones), ground 360 cameras with data from a myriad of field sensors and IoT devices enabling real-time equipment location tracking and performance monitoring, locating construction materials across five laydown areas using RFID technology and more into a single visual interface for site planners, contractors and executives. According to the Shell IT director on the project:

“iHawk has become an inseparable part of what we do, it is now part of the landscape for Pennsylvania Chemicals and for all future Shell projects.”

See the realtime location of your equipment. Anytime, anywhere.

See the realtime location of your equipment. Anytime, anywhere.

Visual data management is not limited to drone imagery. Site inspection imagery, for example, taken in large volumes by quality inspectors and construction engineers, is notoriously difficult to gather, catalog and manage centrally. On this project, Shell and Cyberhawk developed a simple self-service workflow for this kind of content to be captured, uploaded, linked to an equipment tag and assigned keywords in a few clicks, or screen taps on a mobile device. The images can then be instantly shared across the construction project team, for example, to report the need for remediation action.

The Site Master Plan module was developed in response to the needs of the main EPC contractor managing the site. The joint owner and EPC project management team relies on the high-resolution GIS data, developed from drone imagery and enriched with layers of contextualized information, to plan heavy equipment moves and oversized deliveries, organize equipment staging and to manage congested laydown area space across the busy 380-acre construction site.

Historically difficult to manage offline with Gannt charts, space planning clashes and constraints can be instantly detected and resolved in a visual domain. The ability to assign a physical area for a specific task and purpose, assign a responsible individual and publish this information to the stakeholders, is crucial. Not only does iHawk put hundreds of real estate assignments on the timeline and make them visible to everyone on the team, but it also helps to drive personal accountability for the success of every task.

The team uses iHawk to track the position and usage of construction equipment – in this case, the dozens of heavy cranes deployed across the site by seamlessly integrating industry-leading IoT solutions.

The cranes are fitted with vibration sensors that report uptime and other telemetry data, which is aggregated in iHawk for interpretation and analysis, helping the area managers to derive the most value from the investment in the equipment.

Interested to learn how iHawk can support your project?

Download your free capital projects capabilities overview pack now!

The Result

The collection of site imagery captured over time by 360-degree ground cameras and by drones has contributed to countless progress and cost reviews with the major contractors and subcontractors, making them factual, evidence-based and ultimately transparent and fair.

iHawk empowers cross-functional teams to hold each other accountable every day, generating significant value. The monthly cumulative usage of the portal approaches 10,000 hours, exceeding the most optimistic targets and expectations. It is estimated, that every hour of iHawk’s usage translates in the equivalent, often even greater, efficiency gains in the field.

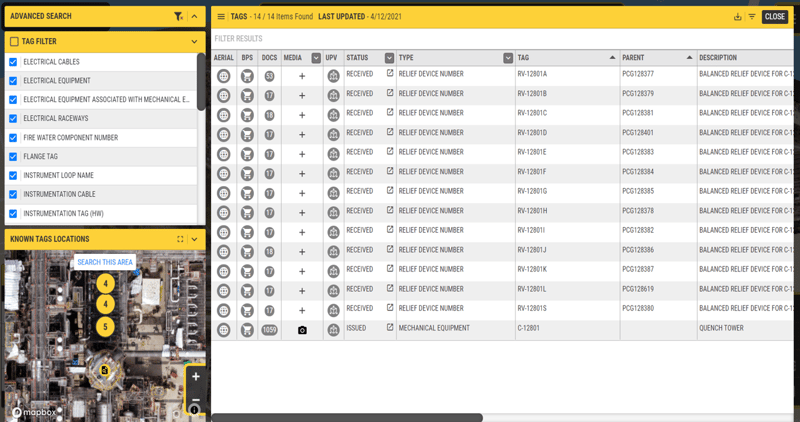

The FindAll module was developed to address one of the most significant challenges inherent to large, complex projects – finding the relevant information quickly. FindAll reaches across multiple databases and information sources, historically disparate, to locate and retrieve engineering, procurement, construction and commissioning documentation and data, up to 90% quicker than some of the traditional methods and tools, saving 3-5 minutes per search. Up to 50,000 searches are performed each month.

Find whatever you need from any source, with FindAll.

What They Said

“Since the introduction of iHawk to the project, we have seen an exponential increase in the usage of the GIS information across critical execution activities such as field engineering, site coordination, environmental monitoring, construction management and workforce planning, materials management and many others.

iHawk has enabled a digital revolution across the owner’s team and the contractor community. We see iHawk as a tool that offers opportunities for safety improvements through increased efficiency and improved visualization prior to work activities."

Get in Touch

If you would like to learn more about iHawk and want to speak with one of our experts, you can get in touch here.